After conducting thorough research on how to create a floatation device for a car the Design Team wrote up a Design Proposal Explaining the project and how they intend to create this device.

ENGR 103 - Fall 2016

Freshman Engineering Design Lab

FCP (Floating Car Project)

Project Design Proposal

Date Submitted: October 03, 2016

|

|

Group Members

Salomon Jose, sj692@drexel.ed

Keyur Patel, khp34@drexel.edu

Antonio Tartaglia, at856@drexel.edu

Micah Watson, mrw83@drexel.edu

Aaron Zehm, amz52@drexel.edu

Technical Advisor Mr. Marco Janko

Abstract:

Millions of dollars worth of damage is caused by floods every year. Floods and flash floods happen in all 50 states often bringing walls of water 10 to 20 feet high. According to thewheatherchannel.com during the time of flash floods a car can easily be carried away by just two feet of water. Strong musty odor in interior or luggage compartment¸ surface rust, dampness of upholstered components, mud or sludge build-up¸ rust on underbody and chassis components¸ mud or sludge build-up inside components, high water marks on door panels and lenses of head and tail lamps¸ deposit of debris etc are all major problems caused by floods to a car.

This calls for a new technology to protect our cars. A technology that can help the car to float over the water but still remain anchored to the ground so that the damage to the car is reduced without endangering other people’s life.

Technical challenges we face are weight distribution of the car, design of the mechanism for anchoring the car and stabilising the car.Major tasks include design of frame, circuits and anchoring mechanisms,3-D printing and fabrication of components,assembling and testing the device..

At the conclusion of the project, a design will be simulated which will reduce the cost to damage that occurs during the flooding. A Portable flotation design frame will be created for a car with an even weight distribution. This flotation device will be activated when a certain water level is reached using sensors.

1. Introduction

As flood rates continue to increase throughout regions of the United States one of the primary cost on individuals is the loss of their car’s, due to water damage. At the conclusion of the project the Design team will have produced a conceptual prototype that will demonstrate the viability of the project on a full scale car. The project will comprise of three distinct areas; frame, sensor, and flotation. The frame will serve to house the method of floatation, likely vinyl bags, attache to a 1/10th model car, and anchor the car to the ground keeping it from floating uncontrolled and possibly causing damage. A sensor will be used to detect a damaging water level and activate a regulator attached to CO2 cartridge(s) filling the floatation bags allowing the car to remain above a damaging water level. Each area provides its own set of distinct challenges including sensor placement, frame design and keeping the car balanced while floating. At the conclusion of the project, team members will have gained a familiarity with the 3D design necessary to create the required parts, structure design for the frame, and basic circuit design necessary for the sensor and regulator.

2. Deliverables

At the conclusion of the project, a design will be created that will reduce the cost to damage that occurs during floods. A Portable flotation design frame will be built for mid-sized cars such as sedans. Portable floatation devices can be added to the car when in emergency or any flood advisory is posted. This flotation device will be activated when a certain water level is reached using sensor technology.

3. Technical Activities

The goal of the Design Project is to create a 1/10 scale size device that could be applied in a real life scenario. In order to do this the Design project will be broken up into three major sections: the frame, the sensors, and the flotation devices. These three components will then be combined into making one optimal mechanism with the sole purpose of assuring no water damage to a car in case of a flood. Through conceptual designs and tested virtual simulations the design team will be able to efficiently produce a balanced product that could save thousands of dollars towards car owners.

3.1 The Frame

Knowing that not all cars have the same length and width dimension creating a frame that could be utilized as “one size fits all” would be extremely expensive. In order to assure the cheapest and most convenient outcome the frame will be modeled to fit a standard mid-size compact car, better known as a sedan, as they are one of the most common car models on the market. Balance is key and assuring a proper weight distribution for the frame distributed throughout the car will provide a safer environment when the floatation device is activated.

Reference Car Frame

3.2 The Flotation Devices

The primary source for the mechanisms’ flotation will be CO2 cartridges, which will be placed in a waterproof pouch that as it inflates will activate the flotation mechanism . These cartridges will be distributed throughout the car according to the different areas of weight distribution. The problem the design team will be facing is the fact that most cars do not have an even weight distribution. The majority of the time the heaviest area of the car is located where the engine is. In order to completely balance the car a proportional distribution of cartridges vs weight will be created.

3.3 The Sensors

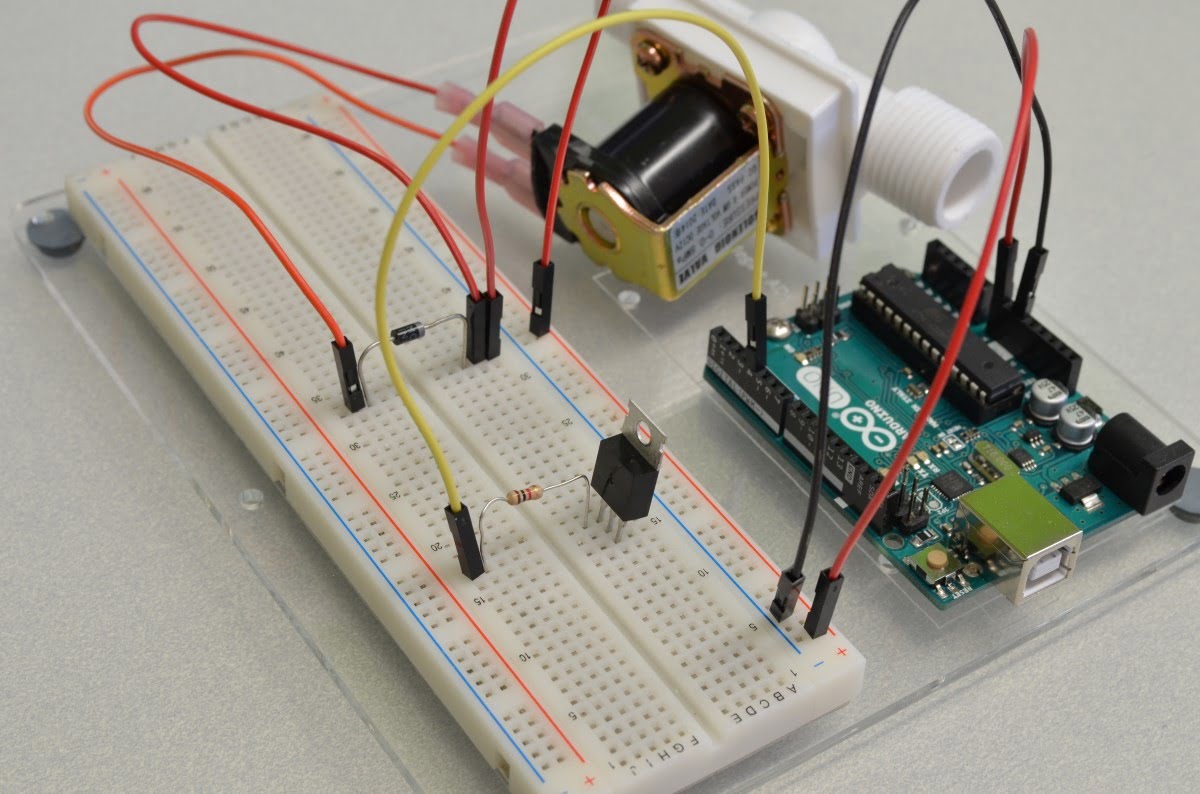

To detect the water level and activate the floatation device (Co2 cartilage) we will use a sensor. The design team will take the ideas of a traditional water level sensor mechanism and adapt it to the personalized flotation device. The problem that the team will be facing here is the placement of the water sensor so that it does not get activated with the rain water. This sensor works on the principle of pressure which states pressure is equal to ( density x gravity x height).

3-D Design Made with Solid Works

4 Project Timeline

The timeline of the Design Project will be divided into theory, experimental, and application. For the first two weeks the design team will conduct theoretical research for applying these concepts to a real life scenario. After a sufficient amount of theoretical data has been collected the Design team will begin conducting experimental trials through virtual simulation and mechanical designs. When the team believes to have created a device that represents their conceptual design the will assemble it all together and give a final deliverable on the device.

|

Week

|

Task

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

Literature study

|

x

|

x

|

|

|

|

|

|

|

|

|

3-D Design

|

|

x

|

x

|

x

|

x

|

x

|

|

|

|

|

Mechanical Design

|

|

|

x

|

x

|

x

|

x

|

x

|

|

|

|

System integration

|

|

|

|

|

|

x

|

x

|

x

|

|

|

Testing

|

|

|

|

|

|

|

x

|

x

|

x

|

|

Final report preparation

|

|

|

|

|

|

|

|

x

|

x

|

x

|

Table 1: FCP Design Project Timeline.

5. Facilities and Resources

Facilities:

The Hagerty library will be where the design team will meet to discuss the project’s goals and create the design proposal along with anything else that doesn’t require working on the physical aspect of the project.

Most of the collaboration will be conducted during the lab session because of the tools and resources available to us at time.

Resources:

A one tenth scale model car will be used to conduct our project on. It will serve as the basis for how the prototype will interact with a semi-realistic model.

The frame of the car will be 3D printed (rapid-prototyping machine) so that we can have it custom made to fit the car and work to the best of our ability.

Creating or purchasing a sensor to detect water in order to deploy the flotation device.

Utilizing machine shop tools in order to assemble the prototype.

A water tank for conducting tests for the prototype in the appropriate scenarios

6. Expertise

The design team is composed of people with all different types of technical expertise. Amongst the design team we have a two Mechanical Engineering majors, two Computer Engineering majors, and one Civil Engineering major. With all of these different backgrounds we are all able to give different and resourceful impacts for the production of the final design.

Computer Programming (C++, Python, Matlab) - For retrieving data from real life scenario

Knowledge of basic circuit theory - For creation of Water sensor

Circuit Design - For creation of Water sensor

3D - Design (AutoCad, Creo, Inventor, Solidworks,Solid edge,CATIA) - For virtual simulation

7. Budget

Category

|

Projected Cost

|

Water Sensor

|

$5

|

1/10 Scale Car

|

$45

|

CO2 Canisters

|

$10

|

Waterproof Pouches

|

$40

|

Anchoring Materials

|

$5

|

Total

|

$105

|

Table 2: FCP Design Project Budget.

7.1 Water Sensor

The water sensors are key into activating the entire process to start the floatation of the car. As the water exceeds a certain level the sensors will detect the water and will be the starting point for the device to start working.

7.2 1/10 Scale Car

The model car will be the main piece of the conceptual design. The other components of the device, frame, sensor, and . Will be attached to the model car to demonstrate the viability of the device.

7.3 CO2 Canisters

The C02 canisters will activate as soon as the water sensors go off. These canisters will then inflate the pouches that they are placed in allowing the car to start floating.

7.4 Waterproof Pouches

The Waterproof Pouches will be containing the CO2 canisters that when the sensors activate will inflate and allow the car to float. These pouches will be securely attached to the frame assuring that the entire mechanism works as one unit.

7.5 Attachment devices

After the car has started to float and the mechanism has been fully activated attachment devices will deploy from the frame acting as an anchor for the car. This will stabilize the car and prevent it from floating away.